PUDU T600

Heavy-payload Industrial Delivery Robot

600 KG Payload Capacity

With a 600 KG payload capacity, the T600 series is built for heavy-payload material transport, greatly reducing delivery frequency and improving efficiency per trip.

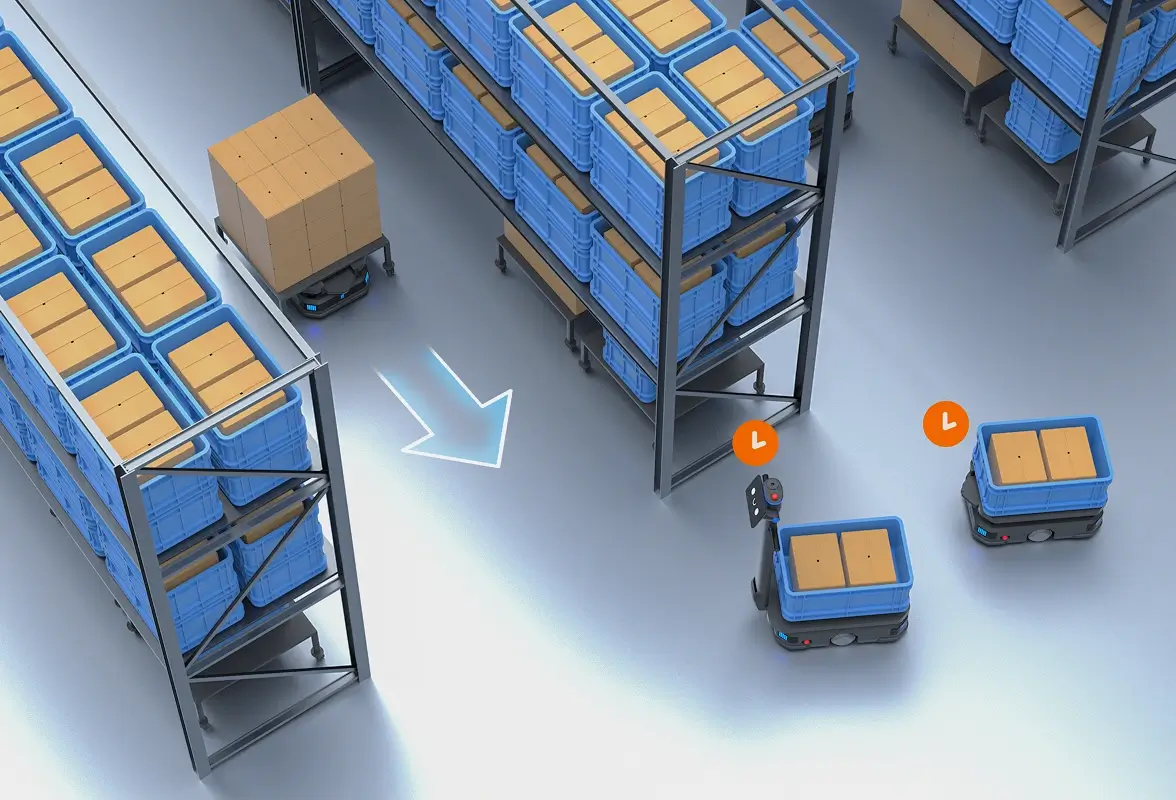

Rack Group Recognition

Powered by advanced navigation and perception systems, the T600 series intelligently identifies target storage locations and autonomously performs pick-and-place operations. This enables fully unmanned workflows, ensuring efficient and reliable warehouse operations.

Idle Elevator Priority Scheduling

In busy multi-elevator scenarios, the system intelligently calls idle elevators first. The smart scheduling algorithm monitors elevator status in real time, prioritizing available elevators to avoid peak-time congestion and resource waste, significantly improving cross-floor delivery efficiency.

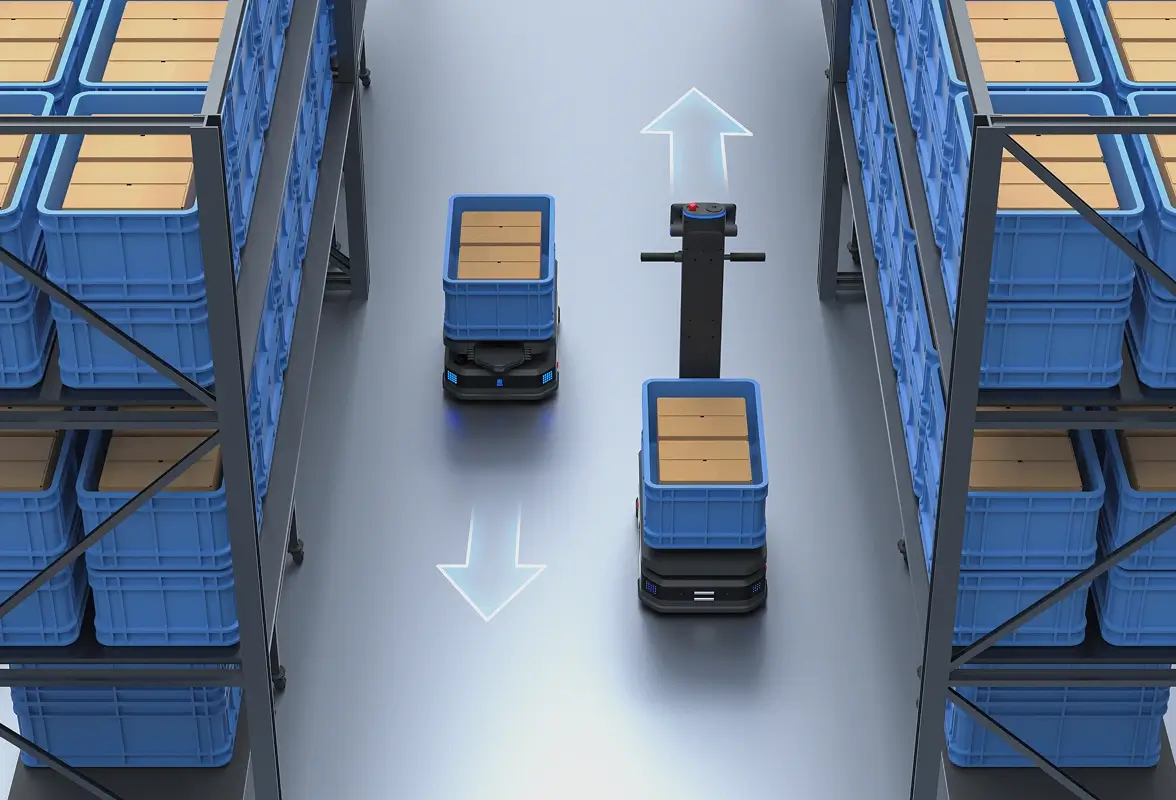

Narrow Aisle Intelligent Traffic Strategy

Based on path width and the robots‘ real-time load dimensions, the system intelligently determines whether to apply single-lane or dual-lane traffic modes. It dynamically adjusts routing strategies to maximize space utilization and improve multi-robot coordination efficiency in narrow environments.

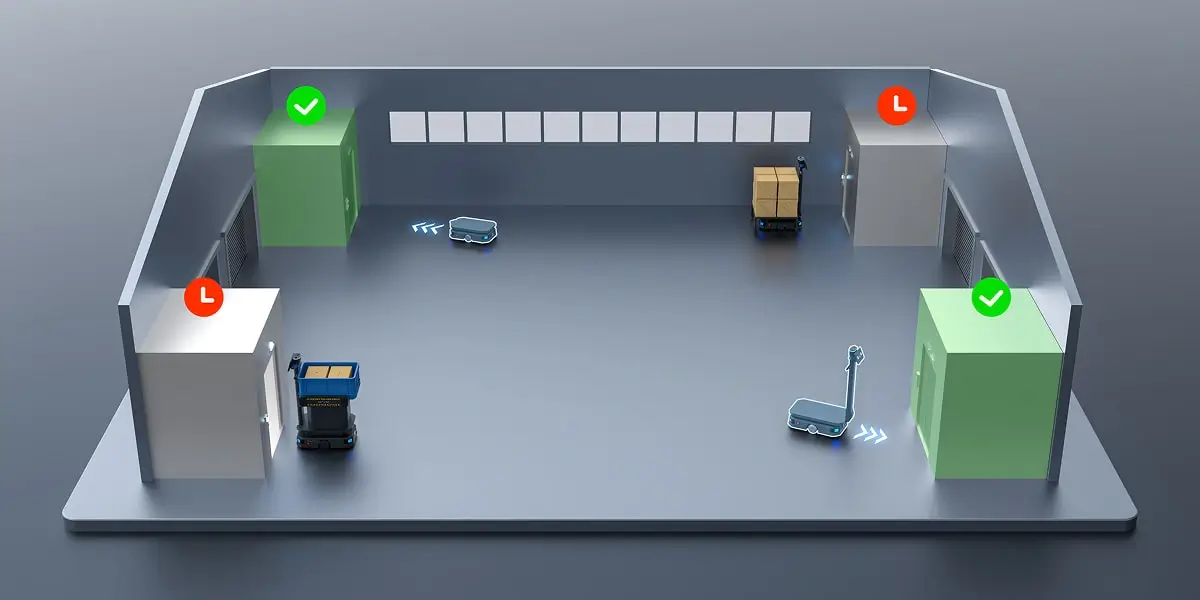

Flexible Deployment

The T600 series can quickly adapt to changes in production layouts without the need for time-consuming reconfiguration or facility modifications.

VDA5050 Protocol

Compatible with the VDA5050 standard communication protocol, enabling collaborative scheduling with other compliant robots and systems. No custom development or complex interface integration is required, allowing for rapid deployment of a unified, efficient, and scalable flexible logistics network.

On-premises Deployment

The system supports on-premises deployment to create a fully controlled and secure operating environment.

Ground Projection

Projects a linear warning mark in front of the T600 to indicate the travel area, creating a safe human-robot collaborative workspace.

Dynamic Obstacle Avoidance

Autonomously detects low obstacles and flexibly navigates around them to ensure safe operation.

Disaster Avoidance Function

The PUDU T600 series is equipped with a dedicated disaster avoidance module that can intelligently receive signals such as fire alarms and earthquakes, and automatically execute avoidance plans: • Autonomous navigation to a safe area. • Intelligent judgment to stop and park at a safe location.

Handle Assist Switch

Equipped with an ergonomic handle assist switch, allowing the operator to easily control the T600 by simply pressing the switch, even when pushing heavy loads.

24/7 Non-stop Operations

The T600 series offers a 12-hour battery life and supports a fast 2-hour charging capability. Equipped with both automatic recharging and battery replacement options, it ensures uninterrupted service to fulfill round-the-clock operational requirements.

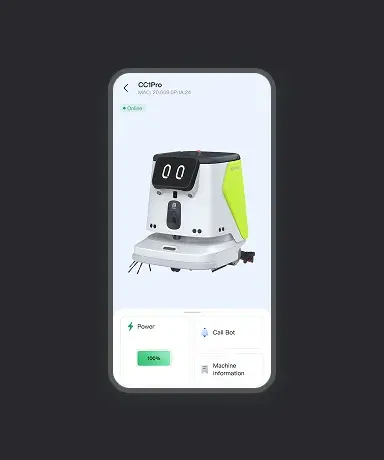

IoT Integration

Dimensions

Weight

Maximum load

Battery Capacity

Charging Time

Run-time

Cruise Speed

Navigation Method

Minimum Passability

Max. surmountable height

Max. surmountable gap

Operating Environment

Dimensions

Weight

Maximum load

Battery Capacity

Charging Time

Run-time

Cruise Speed

Navigation Method

Minimum Passability

Max. surmountable height

Max. surmountable gap

Operating Environment

Frequently asked questions

Success!

We will get in touch as soon as possible

Book a quick call with us.

No strings attached.

Every business is unique, and we'll use our expertise to help you explore the best robotic solution for your needs.